Custom Shims for Precise Solutions

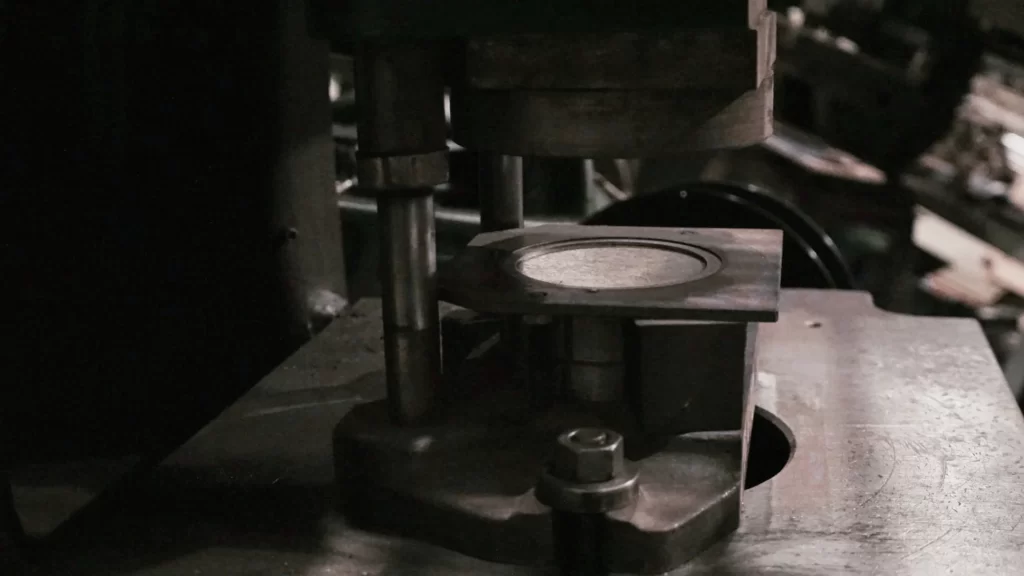

PP Shim not only supplies raw materials and slotted shim kits but also offers custom shim solutions. We provide laser or water jet cutting (outsourced) and have an in-house metal stamping department with various washer sizes. A full-size list is available upon request. Contact us to discuss your custom shim needs for your next project.

We offer in-house guillotining to your required size and can subcontract slitting services. Custom shims are available for all products in our range, including brass, steel, and stainless steel shims. No job is too small or too large!

For custom shim enquiries, call us at 02 4646 1166 or email your drawing to sales@ppshim.com.au for expert advice and fast service.

How to Order in 3 Easy Steps

1. Contact our team

Provide the specifications for your custom shim design.

2. Receive a quote

We’ll provide a competitive price for your custom shim order.

3. Arrange delivery

Have your custom shims shipped or pick them up from our head office.

Custom Shim FAQs

Custom shims play a vital role in various industries, offering precise solutions for alignment, spacing, and load distribution.

- Automotive: Ensures precise alignment and spacing in vehicles and components.

- Aerospace: Provides critical load distribution and precision in high-performance systems.

- Engineering: Supports machinery with accurate alignment and gap adjustments.

- Construction: Assists in structural alignment and load balancing for stability.

Custom shims can be made from materials like stainless steel, brass, copper, and plastic, selected based on factors like durability, flexibility, and environmental resistance.

Custom shims can undergo various surface treatments, such as electroplating for corrosion resistance or polishing for a smooth finish, tailored to enhance durability and functionality.

Yes, custom shims are available in a wide range of thicknesses, from thin, flexible options for fine adjustments to thicker, more rigid ones for heavy-duty applications. Contact our expert team for specific thickness requirements.

Yes, custom shims can be requested in any shape or size. Using advanced cutting technologies like laser and water jet cutting, we ensure precise, tailored solutions for your project. Contact us on 02 4646 1166 for your specific requirements.