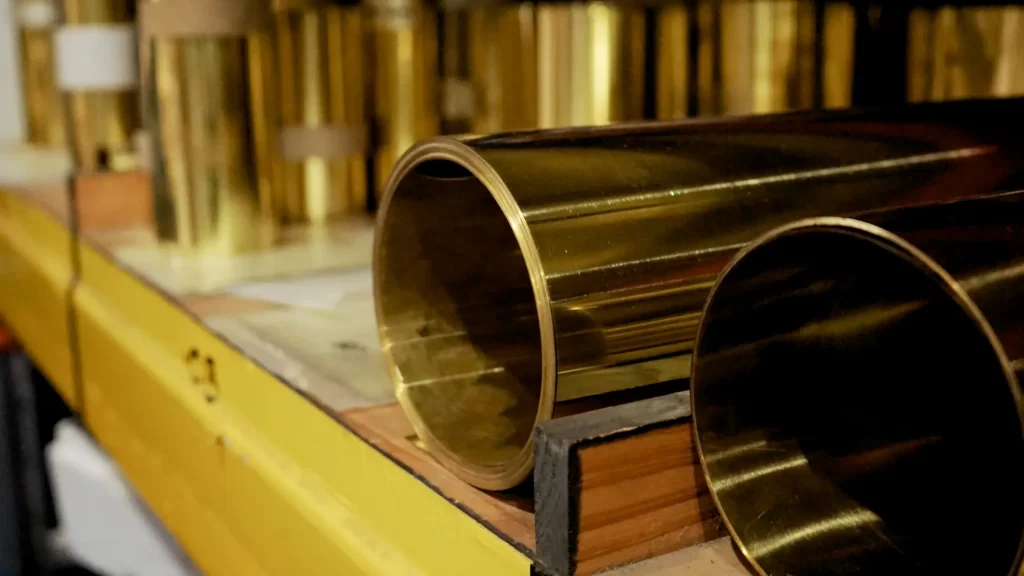

Brass Shim Sheets, Packets & Rolls

Our brass shim sheets come in various sizes and are available in packets or continuous rolls. Made from the C26000 alloy, a copper-zinc blend, brass offers superior cold working strength, excellent ductility, and a bright yellow color. Ideal for shims, gaskets, washers, and circuit board solder masks, it can also be drawn or spun. We also offer pre-cut shims, stainless steel shims, packing shims, and copper shim stock. Explore our complete selection of shim products for all your needs.

Typical Chemical Analysis (% by weight) AS1572-1998

(Chemical Analysis is a guide only)| Copper

Cu |

Iron

Fe |

Lead

Pb |

Zinc

Zn |

| 68.5-71.5 | 0.05 (max) | 0.05 (max) | remainder |

(C26000, 70/30)

Brass Shim stock is cold rolled to a half hard temper of 110-130 VPN. Supplied in a range of sizes from .050mm (.002″) – .508mm (.020″) and is sold in a variety of ways from convenient packets to continuous metres to suit your requirements.

BRASS – Rolls

Also available in continuous metres

| Thickness | 150mm x 1 metre | 300mm x 1 metre | |

| .050mm | .002″ | BR05 | BR053 |

| .076mm | .003″ | BR08 | BR083 |

| .102mm | .004″ | BR10 | BR103 |

| .127mm | .005″ | BR12 | BR123 |

| .152mm | .006″ | BR16 | BR163 |

| .208mm | .008″ | BR20 | BR203 |

| .254mm | .010″ | BR25 | BR253 |

| .305mm | .012″ | BR30 | BR303 |

| .381mm | .015″ | BR40 | BR403 |

| .508mm | .020″ | BR50 | BR503 |

BRASS – Packets

| Thickness | Part # | Packaged | |

| .050mm | .002″ | BP05 | 150mm x 150mm x 6 pieces |

| .076mm | .003″ | BP08 | 150mm x 150mm x 6 pieces |

| .102mm | .004″ | BP10 | 150mm x 150mm x 6 pieces |

| .127mm | .005″ | BP12 | 150mm x 150mm x 6 pieces |

| .152mm | .006″ | BP16 | 150mm x 150mm x 6 pieces |

| .208mm | .008″ | BP20 | 150mm x 150mm x 6 pieces |

| .254mm | .010″ | BP25 | 150mm x 150mm x 6 pieces |

| .305mm | .012″ | BP30 | 150mm x 150mm x 6 pieces |

| .381mm | .015″ | BP40 | 150mm x 150mm x 6 pieces |

| .508mm | .020″ | BP50 | 150mm x 150mm x 6 pieces |

| Assortment | BP1 | 150mm x 150mm (2 x .05mm, .08mm, 1 x .12mm x .25mm) |

|

| Assortment | BP110 | 150mm x 300mm (1 x .05mm, .08mm, .10mm, .12mm, .16mm) (1 x .20mm, .25mm, .30mm, .40mm, .50mm) |

For more information on our range of brass shim or for a quote on brass shim sheet, call us today on 02 4646 1166.

How to Order in 3 Easy Steps

1. Reach out to us

Provide your brass shim requirements for a tailored solution.

2. Request a quote

We’ll send you a competitive price based on your brass shim order details.

3. Select delivery

Opt for shipping or pick up your brass shims from our head office.

Brass Shim FAQs

Brass shim stock is used for precise shimming, gap adjustment, and spacing in mechanical applications. It’s commonly found in machinery, automotive, and manufacturing industries to maintain proper alignment and ensure optimal function.

Choosing the right brass shim stock depends on factors like thickness, size, and mechanical properties for your specific application. Call us at 02 4646 1166 with your requirements, and we’ll assist in selecting the ideal product.

Common sizes are available in a range of thicknesses and widths, as listed above. Brass shims can be customised to suit specific applications, with custom sizes also offered. For exact measurements and requirements, please contact us.

Low Friction: Brass is soft with minimal friction, ideal for spark-sensitive environments. It’s also a great conductor of electricity and heat.

Corrosion Resistance: Brass shims are corrosion-resistant, making them suitable for marine applications and environments with gasoline, alcohol, fuel, and oil.

High Malleability: With its softness and low melting point, brass is perfect for precise alignment, levelling, and gap-filling in machinery.

Recyclable: Brass is easily recyclable and can be separated from other metals using a magnet due to its lack of magnetic properties.

Antimicrobial: As a copper alloy, brass naturally kills microorganisms, making it ideal for use in sterile industries like medical and food sectors.

Brass shims are prized for their malleability and corrosion resistance, ideal for precise adjustments and moisture or chemical exposure. Stainless steel shims, on the other hand, provide superior strength and durability, making them perfect for high-stress applications requiring robust performance.