A shim is an essential component designed to create precise spacing or level surfaces in construction projects. It is widely used across various applications, such as positioning precast tilt-up concrete panels in warehouse construction or aligning window and door frames in residential homes. Shims serve a crucial function by filling gaps in joints or providing support for objects, offering a lasting solution that must be protected from UV exposure.

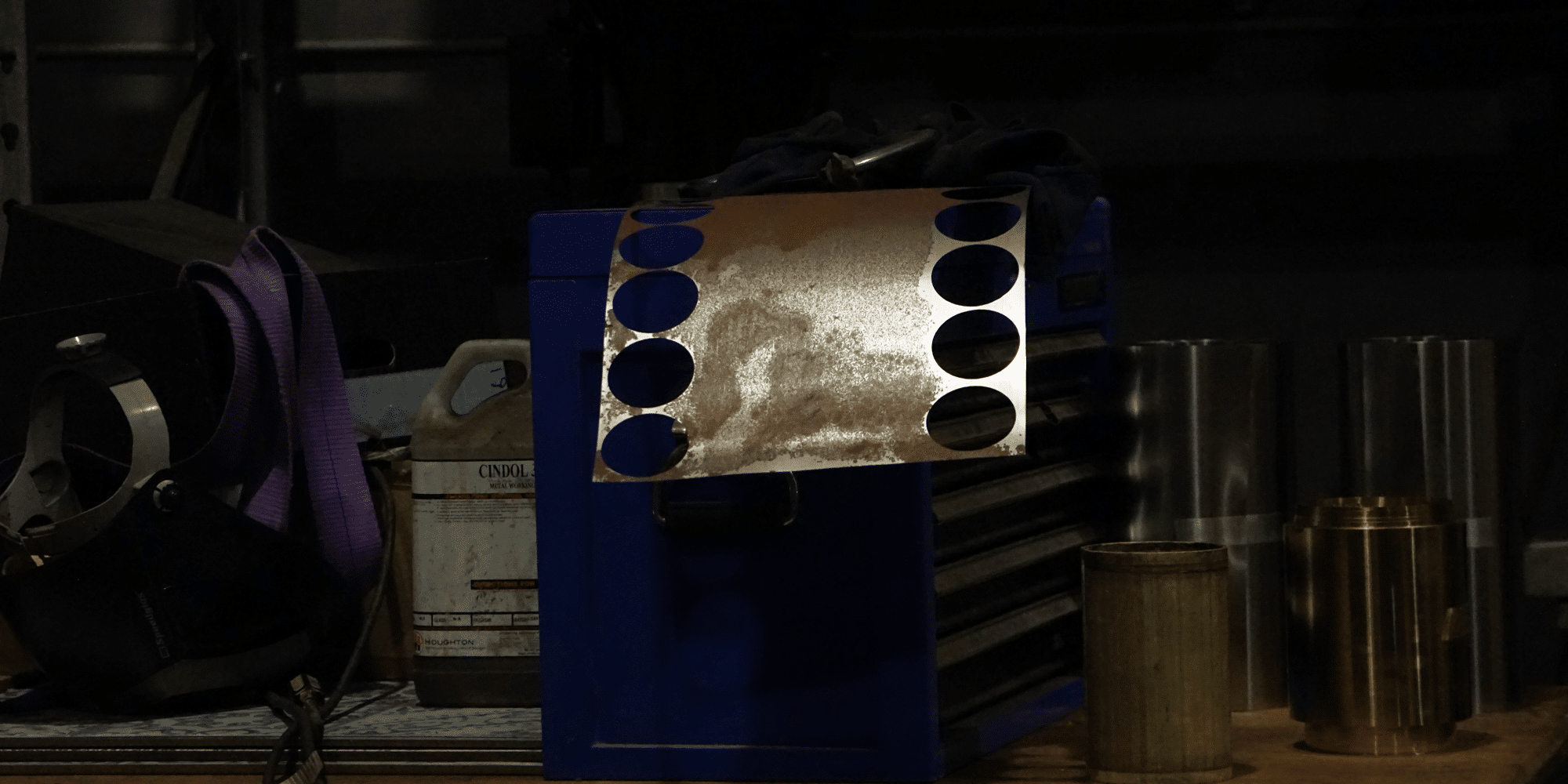

Metal shims can be produced to meet a wide range of specifications. When opting for custom-made metal shims, selecting the appropriate material is a key decision. At PP Shim, we offer high-quality, precise manufacturing for all our shim stock, providing a comprehensive range of metal shims, including stainless steel, copper, and brass.

Plastic shims and packers are built for convenience and provide remarkable versatility. Their applications are virtually limitless, as they can be screwed, stacked, drilled, nailed, or cut to suit a variety of needs. Whether used in construction, assembly, or repairs, plastic shims adapt to a wide range of tasks.

The Main Differences

Both metal and plastic shims are essential components used across various industries, each offering unique characteristics. They play a crucial role in providing precise alignment, spacing, and support in different settings. Choosing between metal and plastic shims depends on factors such as the specific application, environmental conditions, and performance requirements.

Both materials have their advantages and drawbacks, making it important to select the right type of shim stock for the task at hand. Let’s explore the differences between metal and plastic shims in terms of their applications, benefits, and limitations.

Applications, Benefits & Limitations of Metal Shims

Metal shims are highly versatile and used in a variety of industries. They are critical in heavy machinery, construction, and structural adjustments, providing necessary support and precision. Additionally, metal shims are widely used in the automotive and aerospace industries, where reliable performance is essential under extreme conditions.

A key advantage of metal shims is their exceptional strength and durability. They are capable of handling significant loads and maintaining stability, offering precise alignment for various applications. Custom fabrication allows them to meet specific requirements, making them ideal for demanding industrial tasks.

However, metal shims have some limitations. They are prone to corrosion if not treated properly, which can impact their performance and lifespan. Additionally, metal shims tend to be more costly than plastic shims and may require extra effort for on-site modifications, making them less flexible in some situations.

Applications, Benefits & Limitations of Plastic Shims

Plastic shims are versatile components used in a wide range of settings, both indoors and outdoors. They are ideal for projects such as window installations and furniture adjustments, where their adaptability is an advantage. Their application extends to various home improvement and light construction tasks.

One of the standout features of plastic shims is their lightweight nature, making them easy to handle and install. They are resistant to moisture and corrosion, ensuring durability in different environments. Moreover, they are generally more cost-effective than metal shims, making them an economical choice for many projects.

Despite their advantages, plastic shims have some limitations. They may not offer the same level of strength as metal shims, particularly in heavy-duty applications requiring robust support. This limitation can restrict their use in scenarios where substantial load-bearing capacity is necessary.

Understanding the differences between metal and plastic shims is crucial when selecting the right type for your specific needs. Both types of shims play vital roles in a variety of applications, from heavy-duty industrial uses to everyday home improvements.

Selecting the right shim involves considering the specific demands of your project. By weighing the advantages and limitations of both materials, you can make an informed decision that ensures optimal performance and longevity.

Whether you require the robust support of metal shims or the adaptable nature of plastic shims, PP Shim is your expert shim stock provider in Australia. For metal shims, plastic shims, or any other type of shim stock, contact us at 02 4646 1166 and let us know how we can assist you.

Ordering Metal & Plastic Shims is Simple

1. Get in touch

Let us know what 316 stainless steel shims you need.

2. A quote is given

We’ll provide you with a price for your 316 stainless steel shim order.

3. Delivery

We can ship your 316 stainless steel shims or you can pick it up from our head office.